- Home

- Unternehmen

- Vertriebspartner in den USA

- Aerospace

Aerospace Sealing Solutions

Garlock delivers aerospace manufacturers precision-engineered sealing solutions built for mission-critical reliability to improve performance, streamline production, and ensure compliance.

Aerospace OEMs and Tier 1 suppliers worldwide rely on precision-engineered sealing solutions for mission-critical reliability. Garlock's AS9100 certification of the Houston, Texas facility reflects a proven commitment to consistent quality, traceability, and reliability. With advanced in-house capabilities, including precision laser cutting, cleanliness-controlled manufacturing, and compression testing, we help customers reduce risk, improve performance, and maintain compliance across flight-critical systems. Explore our aerospace certified products and manufacturing capabilities below.

Metal Gaskets for Aerospace

AS9100 Certified Spiral Wound Metal Gasket Products: Precision-Cut, Performance-Tested, and Built for Reliability

Garlock manufactures custom spiral wound metal gaskets for aerospace OEMs with a strict focus on quality and compliance. Available in a wide range of sizes and alloys including INCONEL® and stainless steel. With decades of sealing expertise, our team ensures every gasket meets exacting standards for safety and reliability.

Metal Gasket Manufacturing Capabilities

General Clean Services

We use low-chloride, high-purity graphite and heat-sealed packaging to minimize ionic contamination and preserve material integrity.

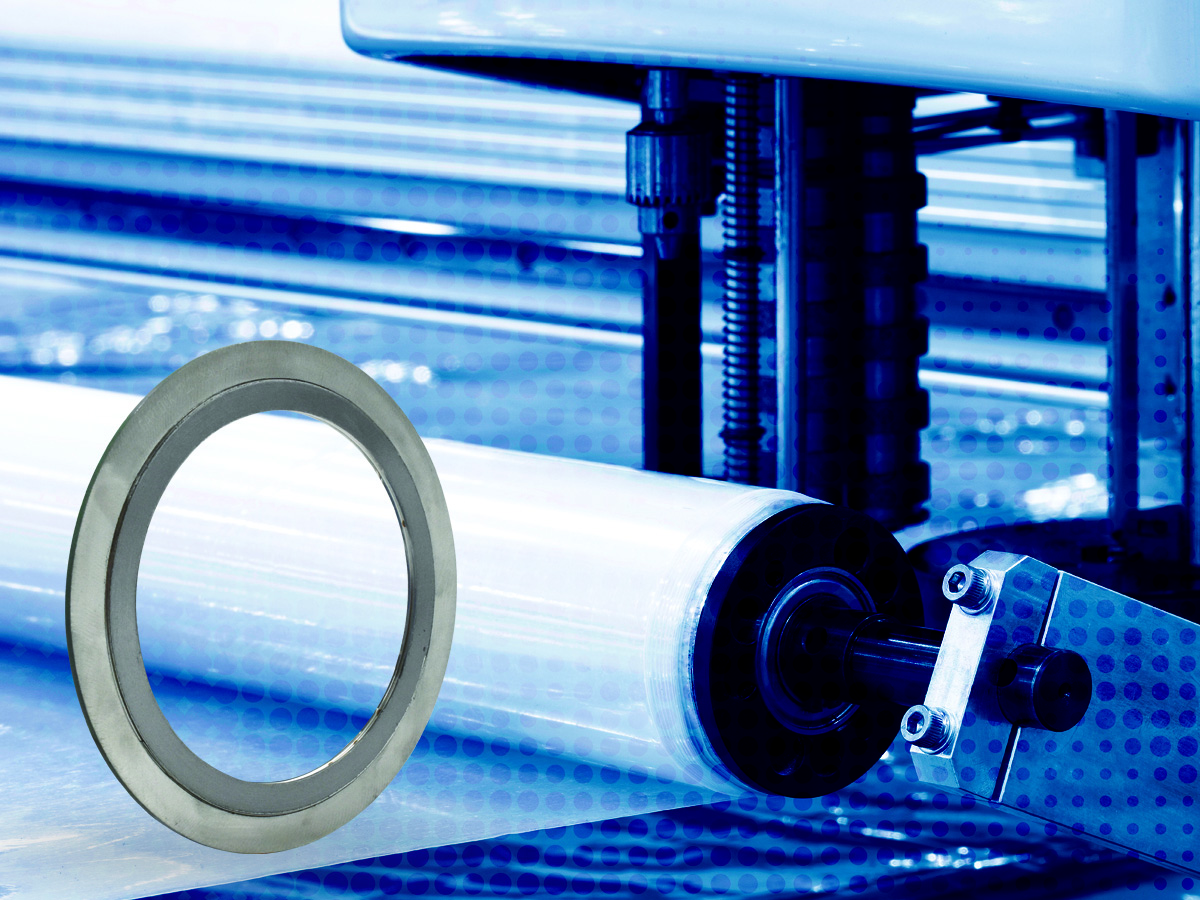

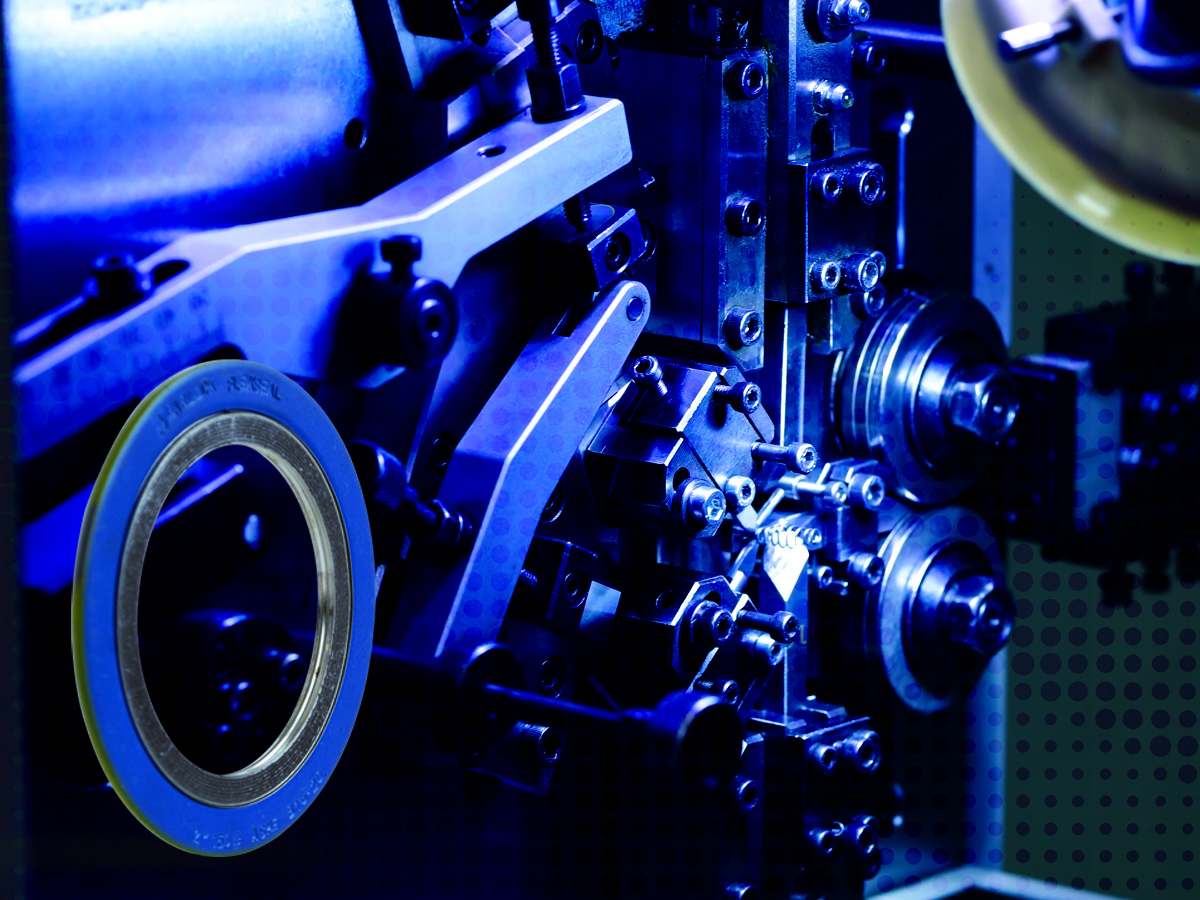

Winding Operations

Custom-engineered parts for high-pressure, high-temperature applications with a wide range of filler materials and alloys.

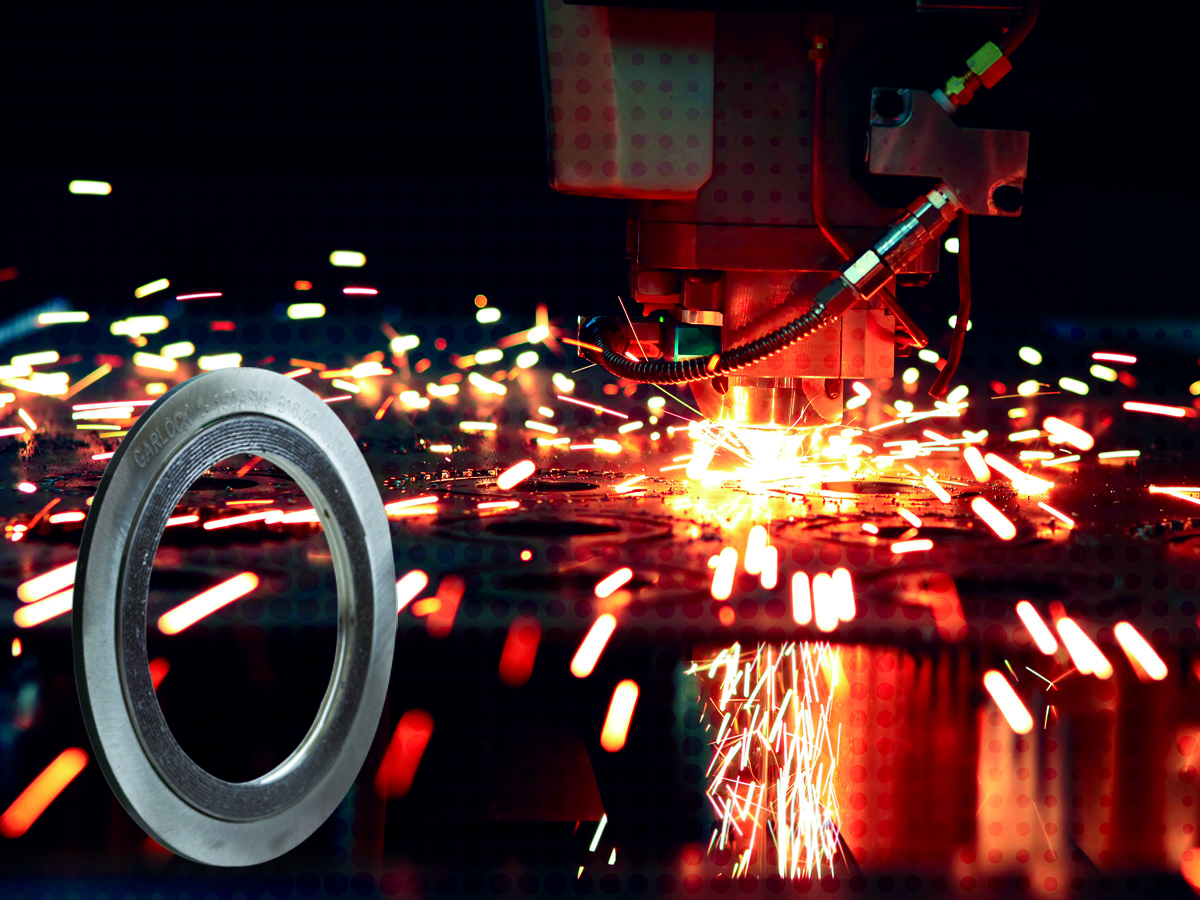

Flash Cutting

CNC-controlled flash cutting of elastomers, graphite, and metal-inserted composites enables repeatable production of complex gasket geometries with clean edges and minimal material waste.

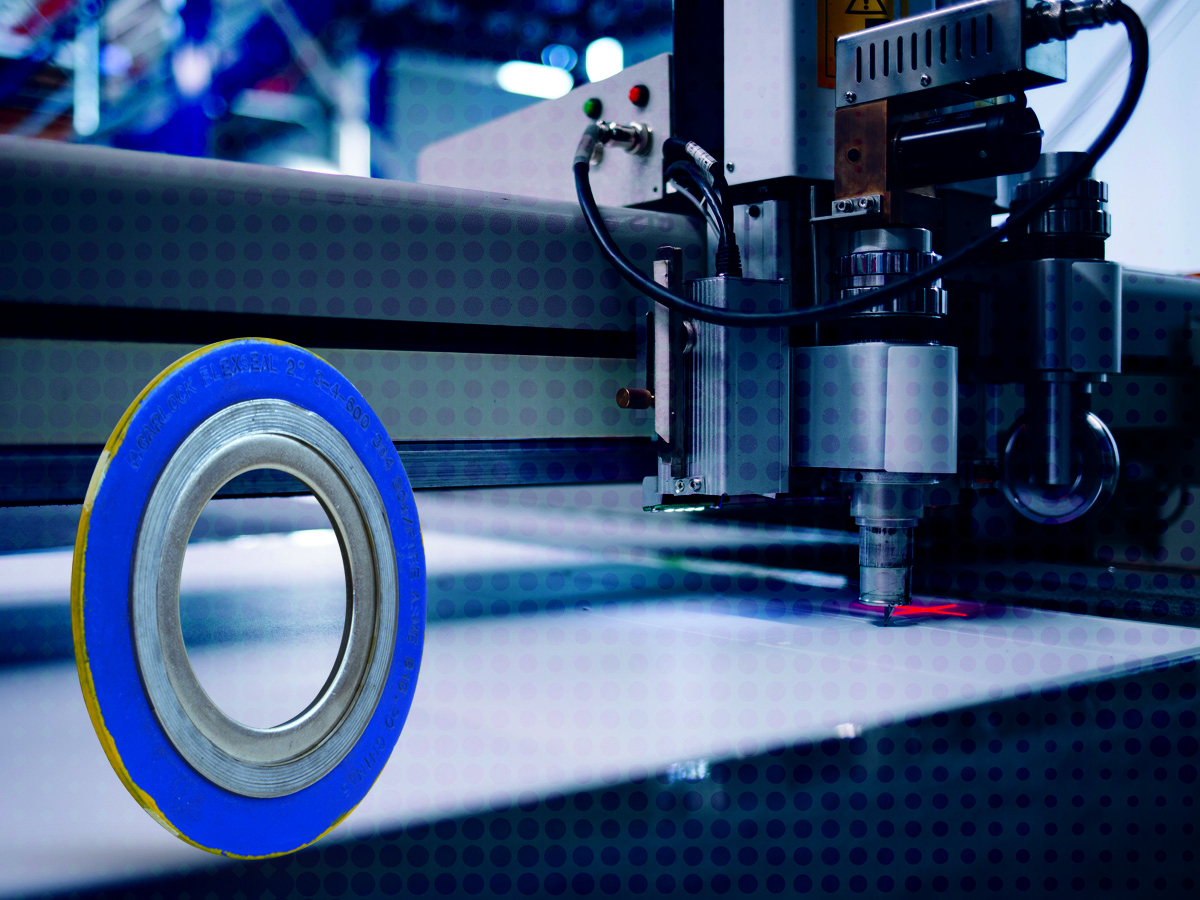

Laser Cutting

High-speed fiber laser cutting with micron-level accuracy for metallic and non-metallic components, ensuring compliance with exacting dimensional and surface finish requirements.

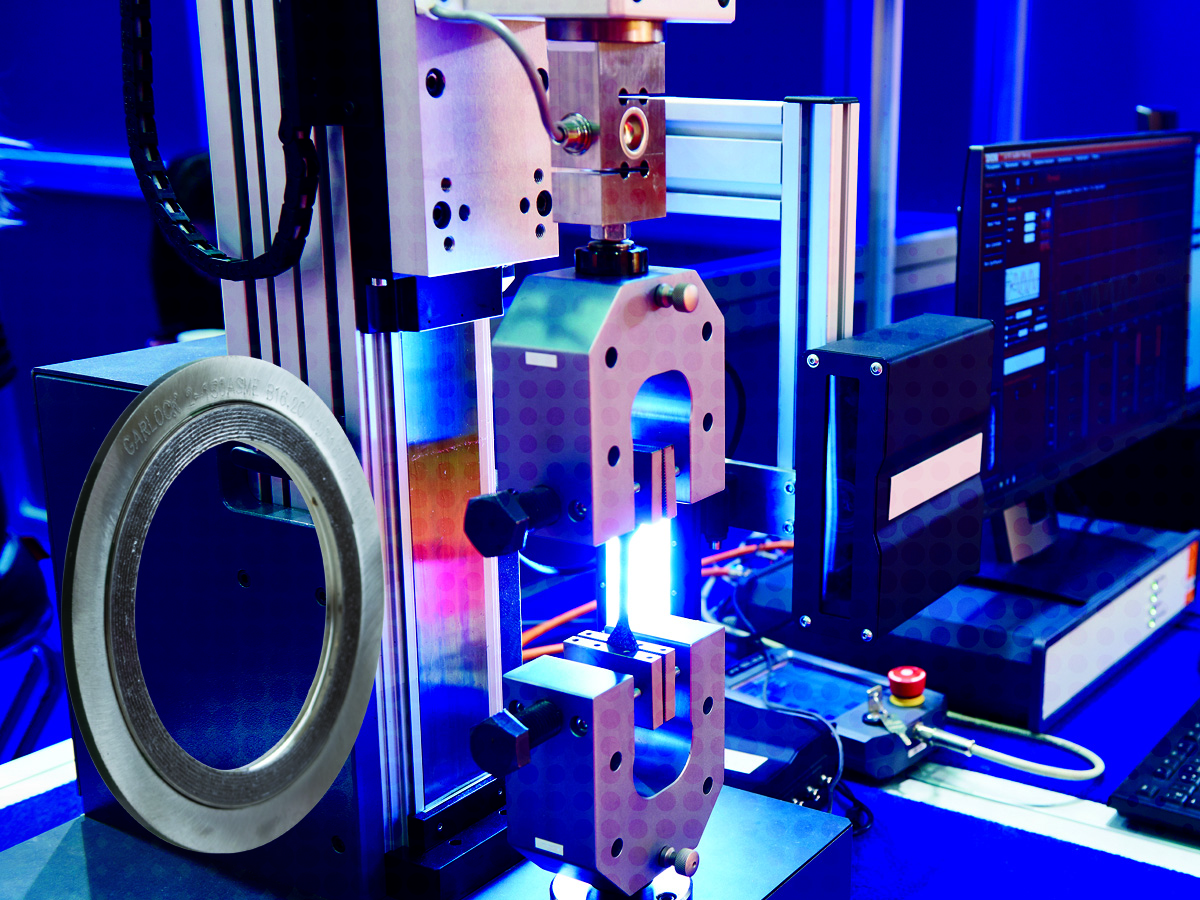

Compression Testing

In-house compression and recovery testing validates material resilience, dimensional stability, and long-term sealing performance.