- Home

- Secteurs

- Data Centers

- Data Centers

Trusted Partner for Data Center Sealing

Safeguarding uptime with advanced sealing for high-performance cooling and power infrastructure.

True data center resilience relies on a leak-free mechanical backbone that extends from the utility yard to the server rack. Garlock delivers specialized sealing integrity across the three critical operational zones: Facility Water Systems (FWS), Technology Cooling Systems (TCS), and Power Generation. Whether managing high-volume facility cooling, protecting sensitive precision loops, or ensuring power and backup power readiness, our solutions are engineered to safeguard your infrastructure against downtime at every connection point.

The Data Center Reliability Challenge

The cost of downtime is rising. As AI and HPC (High Performance Computing) workloads drive rack densities toward 100kW+, the margin for error in critical infrastructure has vanished.

- Escalating Heat Loads: Transitioning from air to liquid cooling introduces complex fluid piping where a single drip can compromise adjacent compute hardware.

- Chemical Compatibility: Modern dielectric fluids and glycol-water mixtures require specialized material matching to prevent seal degradation over time.

- Power Redundancy: Backup generation systems must perform instantly after months of standby, withstanding rapid thermal cycling without failure.

- Zero-Tolerance Operations: Component reliability is not optional. Sealing solutions must match the lifespan of the infrastructure they protect.

Leak-Free Performance for Liquid Cooling Architectures

The shift to liquid cooling introduces complex fluid loops across data center infrastructure, from Facility Water Systems (FWS) to Technology Cooling Systems (TCS), where seals must do more than just contain water. They must maintain integrity against aggressive coolants and conform to lightweight, precision-engineered hardware.

The shift to liquid cooling introduces complex fluid loops across data center infrastructure, from Facility Water Systems (FWS) to Technology Cooling Systems (TCS), where seals must do more than just contain water. They must maintain integrity against aggressive coolants and conform to lightweight, precision-engineered hardware.

- Universal Chemical Compatibility: Liquid loops use specialized inhibitors and fluids that can degrade standard elastomers. Our materials are validated for broad resistance to propylene glycol/water mixtures (eg. PG25), refrigerants, and emerging dielectric fluids.

- Sealing HDPE & Low-Load Piping: FWS often utilize HDPE and plastic piping which cannot withstand high bolt torque. Garlock offers several sealing solutions that provide ultra-tight seals under the extremely low compressive loads required to protect plastic flanges.

- Optimized for Lightweight Stainless Steel: To reduce structural weight, cooling manifolds often use Schedule 10 (thin-walled) stainless steel. These lighter flanges distort under heavy clamping force. We engineer stress-optimized gaskets that seal with significantly lower bolt load, preventing flange deformation/bending while maintaining integrity.

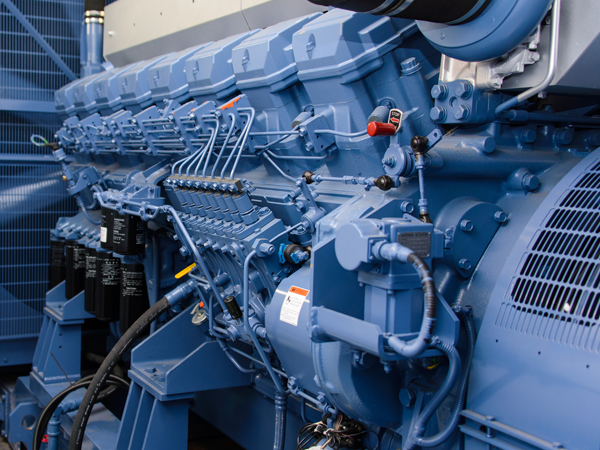

Securing Energy Resilience: From Prime Power to Backup

Data centers are evolving from passive consumers to active power generators, relying on advanced sealing for onsite generation, microgrids, and mission-critical standby systems. Garlock solutions bridge the gap between the sustained high-heat demands of prime power and the violent thermal shock of emergency backup systems.

- Prime Power & Microgrids (Continuous Duty): For onsite power generation (natural gas turbines, hydrogen fuel cells), seals must endure sustained high temperatures (>1,470°F / 800°C) and constant vibration without degrading over thousands of operating hours.

- Backup & Standby Systems (Cyclic Duty): When the grid fails, backup engines must fire instantly. Garlock gaskets are engineered to survive and maintain integrity during thermal shock, going from ambient to high operating temperatures in seconds.

- Future-Fuel Readiness: As the industry adopts lower-carbon fuels, our materials are tested and ready for the lower viscosity of HVO (Hydrotreated Vegetable Oil) and the high permeability of Hydrogen and natural gas blends.

- Heat Reuse & Exhaust: Supporting heat reuse initiatives, our high-temperature seals ensure leak-free performance in exhaust heat recovery systems, preventing exhaust gas bypass and maximizing thermal capture efficiency.

Engineering Confidence Into Critical Infrastructure

- OCP (Open Compute Project) Aligned: We actively participate in OCP projects and monitor OCP guidelines to ensure our solutions adhere to the highest industry standards for reliability and quality.

- Global Material Consistency: Whether you are building in Northern Virginia, Singapore, or Dublin, our global manufacturing ensures the exact same specification and quality everywhere.

- Material Science Authority: With decades of experience in the most demanding chemical and nuclear industries, we bring a higher standard of safety to the data center.

- Support from Design to Operation: We partner with EPCs and OEMs during the design phase to specify the right seal, preventing costly retrofits later.

- Connect with an engineer to talk through custom solutions today.