PS-SEAL® PTFE Rotating Shaft Seals

Advanced rotary shaft sealing designed for industries that demand maximum reliability, extended service life, and protection against contamination.

Where others fail, PS-SEAL® reliably seals rotating shafts at high circumferential speeds, high pressures, and extreme temperatures. PS-SEAL® offers exceptional wear resistance, low friction, chemical compatibility, and full compliance with FDA, USP VI, EN 1935/2004, and ATEX standards, making it ideal for food, beverage, and pharmaceutical industries.

Available in a wide range of lip materials and geometries tailored to abrasion, adhesion, dry running, vacuum, or chemical service, the PS-SEAL® utilizes high-performance GYLON® modified PTFE to maintain contact between the seal and shaft. The result is a seal that can withstand pressures up to 50 times that of standard lip seals, surface speeds up to 45 m/s, and temperatures up to 500º F (260ºC).

Click here for a library of PS-SEAL® resources, such as case studies and product literature, or learn more via one of our product videos.

Industries & Applications

PS-SEAL® is trusted in food, beverage, pharmaceutical, chemical, and industrial processes where traditional seals fail. It thrives in mixers, grinders, conveyors, pumps, dosing systems, separators, and gearboxes exposed to pressure, heat, vacuum, or abrasive media. With FDA, USP VI, EN 1935/2004, and ATEX standards compliance, it meets strict hygienic standards while its chemical resistance ensures reliability through aggressive CIP/SIP cleaning and challenging production cycles.

Protecting Against Contamination

Contamination is a constant risk in hygienic and chemical processing. PS-SEAL® reduces that risk with a smooth surface, cleanable design, and PTFE materials that resist bacteria, debris, and aggressive cleaning agents. By sealing out foreign particles and maintaining integrity through repeated CIP/SIP sanitation, it helps protect product quality, reduce downtime, and ensure compliance with food, pharma, and chemical safety standards.

Tailored Lip Materials and Configurations for Tough Challenges

PS-SEAL® can be customized to the exact demands of your process. With multiple lip geometries and an array of PTFE-based materials, it can be configured to withstand abrasion, adhesion, dry running, vacuum service, or aggressive chemicals. This flexibility ensures each seal is optimized for uptime, reliability, and compliance in the most challenging applications.

Low Lead Times, No Minimum Orders

Garlock makes it easy to get the right seal when you need it. PS-SEAL® is available with short lead times and no minimum order requirements, giving you fast access to proven sealing solutions for urgent or one-off needs. Engineering support is on hand to help match lip and material options to your exact process conditions, ensuring every seal is optimized for reliable performance.

PS-SEAL® Product Videos

View the videos below to learn more about Garlock's PS-SEAL® and see it in action.

Ask an Engineer - Solving Challenges for Sealing Mixer Shafts

Introducing the PS-SEAL® by Garlock

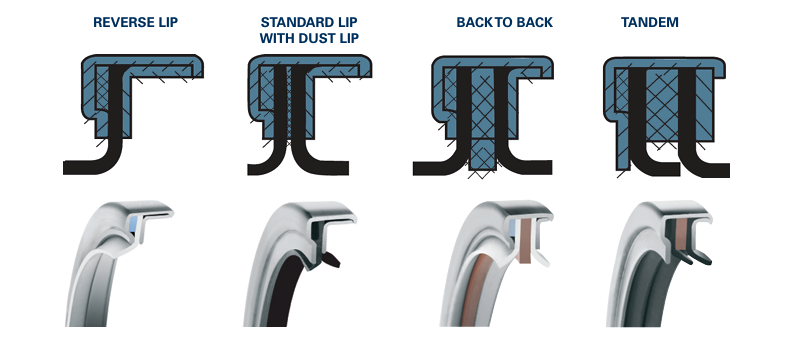

PS-SEAL® Lip Configurations

Available Lip Materials

| LIP MATERIAL | INGREDIENTS | PROPERTIES | COLOR |

|---|---|---|---|

| GYLON® BLACK | Graphite | » standard material » perfectly suitable for lubricated applications |

Black |

| GYLON® WHITE | Barium Sulfate | » special material » FDA EN1935 conformity » recommended for food, pharmaceutical and beverage industries » partially capable of dry running |

White |

| GYLON® BLUE | Glass-Microspheres | » special material » FDA EN1935 conformity » very flexible (high recovery capacity) » recommended for food, pharmaceutical and beverage industries » brilliant dry running characteristics |

Blue |

| GYLON® BROWN-WHITE | Brown side: Abrasive-resistant additives White side: Heat dissipating additives |

» special material » FDA EN1935 conformity » very flexible (high recovery capacity) » recommended for food, pharmaceutical and beverage industries » suitable for abrasive media |

|

| F | Econol | » special material » FDA EN1935 conformity » recommended for food, pharmaceutical and beverage industries » suitable for vacuum-applications » brilliant dry running characteristics |

Tan |

| MS | Molybdenum Disulfide | » special material » suitable for abrasive media |

Black |

| KF | Carbon Fiber | » special material » suitable for partial-abrasive media » good dry running characteristics |

Black |

PS-SEAL® Resources

PS-SEAL® Product Literature

PS-SEAL® 3D Models

PS-SEAL® Case Studies

- Case Study: Extending Seal Life in Hotdog Processing with Garlock PS-SEAL®

- Case Study: PS-SEAL® with GYLON® Style 3504 Food and Pharmaceutical

- Case Study: PS-SEAL® with GYLON® Style 3504 Food and Beverage/Snack Production

- Case Study: PS-SEAL® with GYLON® Style 3504 Food and Beverage

- Case Study for Garlock PS-SEAL® with GYLON® White in Food and Pharma Bulk Handling Systems

GYLON® PTFE Lip Seal Product Videos

- 3-D Mixer Seal Application Video

- More coming soon!