- Home

- 美国经销商

- Data Centers

- Sealing Solutions for Data Centers

Advanced Sealing Solutions for Data Centers

High-performance sealing solutions for the cooling and power generation systems that keep data centers running.

Garlock is proud to support the evolving data center market with a comprehensive portfolio of sealing solutions designed for thermal management and energy resilience. From high-purity fluid cooling loops to high-temperature power generation systems, our products are engineered to withstand the unique mechanical and chemical challenges of the modern data center. We focus on providing innovative, high-quality components that ensure long-term reliability and leak-free performance. Use the sections below to find the right sealing technology for your cooling or power generation requirements.

Explore Data Center Sealing Solutions for Every Stage:

Data Center Cooling

Fluid Water Systems (FWS) and Technology Cooling Systems (TCS) keep data centers running by delivering precise coolant flow across heat exchangers, pumps, and distribution networks. High pressures, water-glycol and refrigerant chemistries, continuous cycling, and numerous connection points demand advanced sealing performance. Garlock provides engineered solutions that prevent leaks, protect uptime, and ensure reliable cooling under critical conditions.

MULTI-SWELL™ Style 3760 Pipe Flange Gaskets

Data centers rely on steel and HDPE liquid-cooling distribution loops to transport water-glycol or refrigerant-based coolants between chillers, coolant distribution units (CDUs), and heat-exchange equipment. Even small leaks can disrupt IT operations and facility uptime. Garlock MULTI-SWELL™ Style 3760 creates its own compressive load when exposed to water, maintaining a tight seal in low-load flanges where rubber or fiber gaskets may crush or weep over time. Recognized by the Plastic Pipe Institute for use with HDPE flanges, MULTI-SWELL™ helps ensure cooling system integrity.

Gasketing

STRESS SAVER® Style 3522

- Seals non-metallic flanges at lower torque

- High purity, non-contaminating

- Excellent chemical resistance

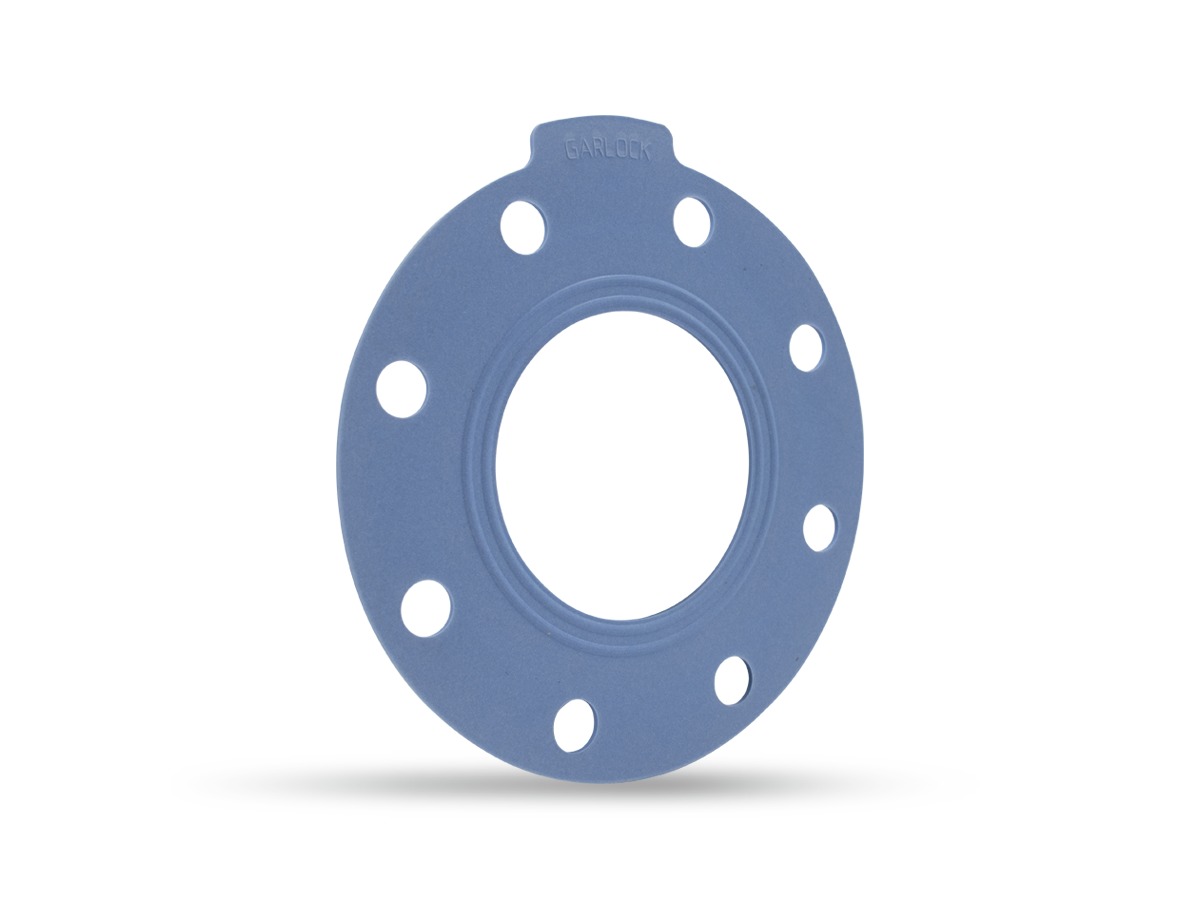

STRESS SAVER® Style 3504

- Lubrizol FBC™ System Compatible for CORZAN® piping

- Seals non-metallic flanges at lower torque

- Excellent chemical resistance

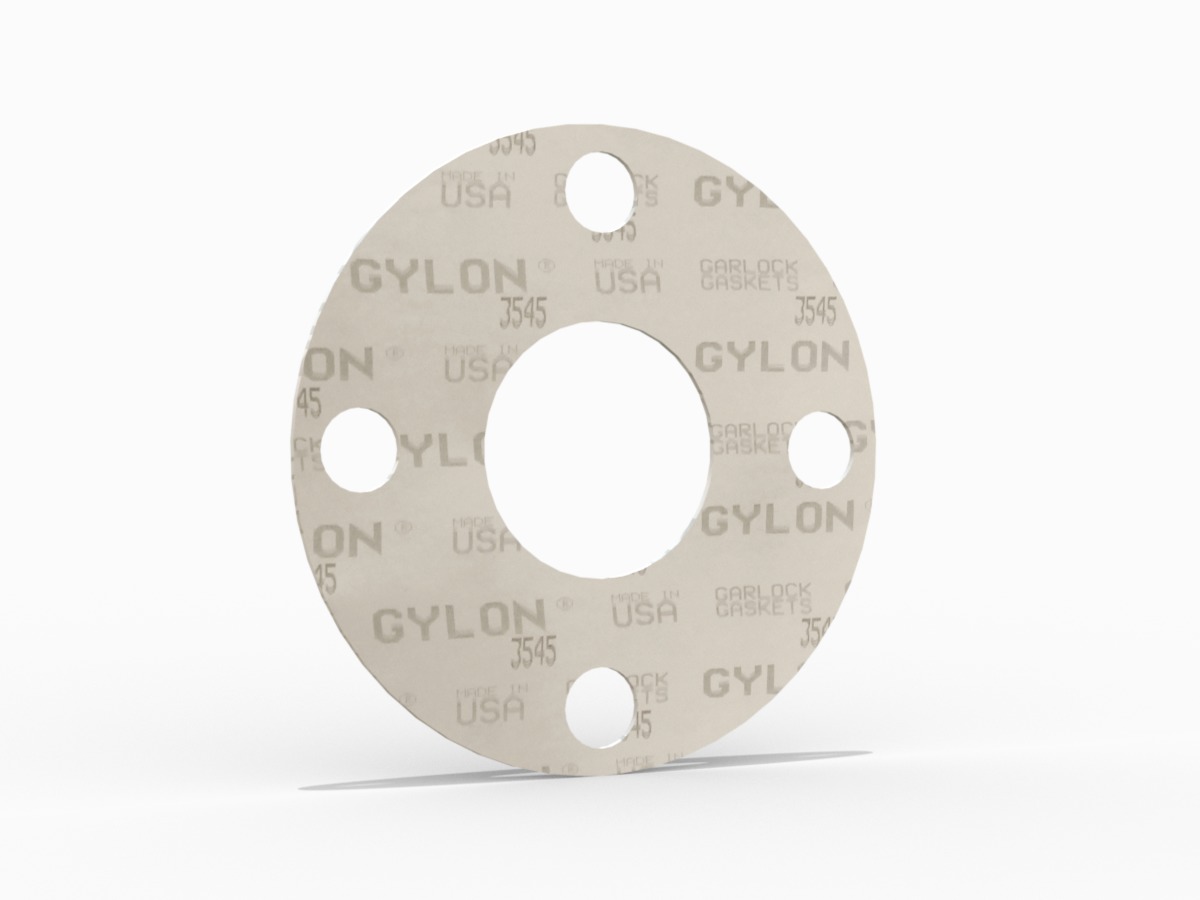

GYLON® Style 3545

- Great for raised face metallic and HDPE connections

- Seals imperfect flanges with ease

- Excellent chemical resistance

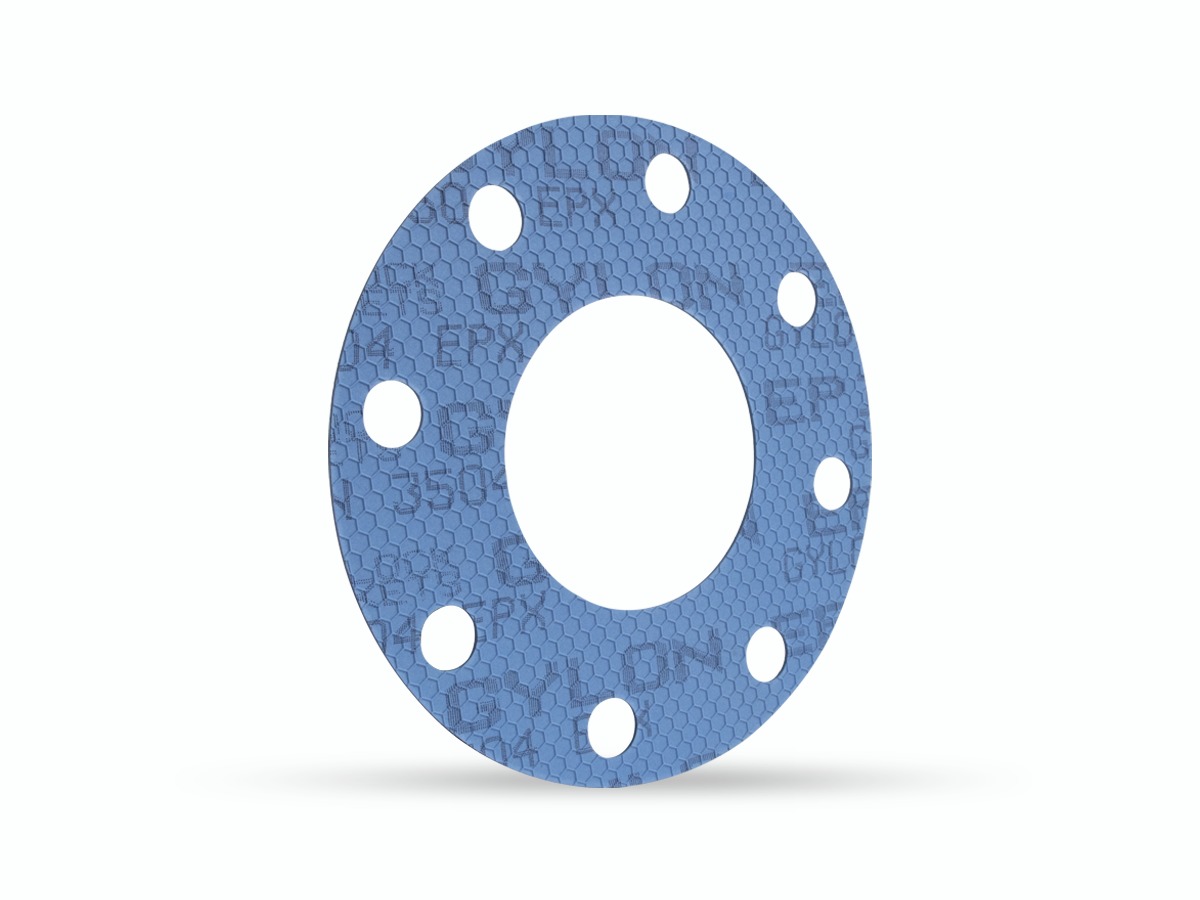

GYLON EPIX® Style 3504

- Seals well in raised face metallic and flat face FRP flange connections

- Excellent chemical resistance

Additional Sealing Solutions

LINK-SEAL® Modular Wall Penetration Seals

- Protects equipment from water intrusion and environmental damage

- Lasts longer than grout or mastic

- Reduces vibration and chemical exposure

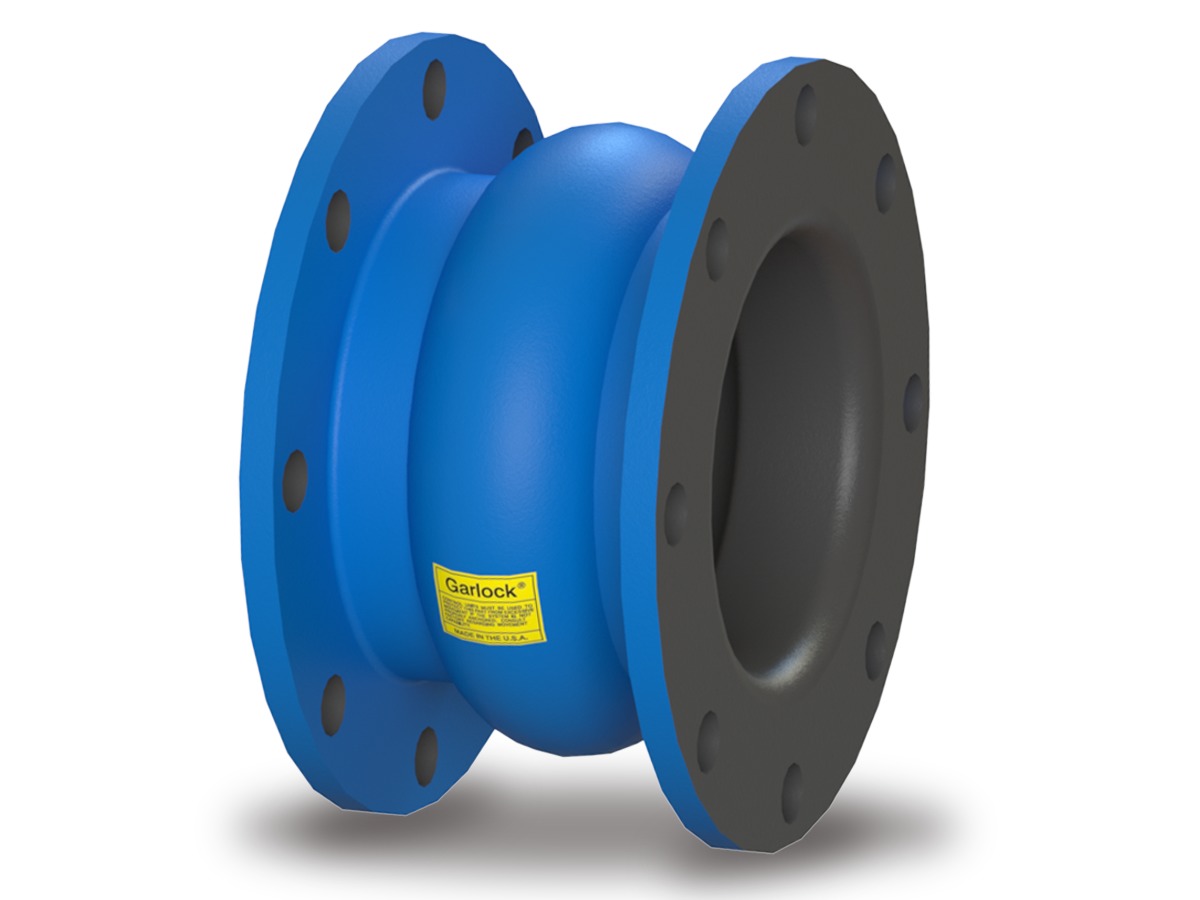

Style P2000 Expansion Joints

- Absorbs movement to protect system components

- Isolates vibration to reduce noise and damage

- Delivers durability for high-demand cooling systems

Style 8922 Compression Packing

- Ensures leak-tight performance for valves and pumps

- Maintains stability under thermal and pressure changes

- Reduces wear and unplanned maintenance

KLOZURE® Bearing Isolators

- Prevents ingress of contaminants and egress of lubricants

- Improved motor and pump bearing service life

- Patented Cam-Lock O-ring grooves for secure hand installation and reduced misalignment during installation

- Unitized design eliminates metal shavings from rotor/stator contact

Data Center Power Generation

For the critical power systems that sustain data center operations, Garlock provides sealing integrity you can trust. We leverage our industrial engineering heritage to deliver robust components capable of surviving the extreme heat, harsh chemicals, pressure, and vibration of power generation infrastructure. Our portfolio of heavy-duty gaskets and expansion joints effectively isolates exhaust and fuel systems from failure, ensuring that when the grid goes down, your facility remains operational. From diesel generators to gas turbines, Garlock safeguards the continuity of your power supply.

THERMa-PUR® Extreme Heat Pipe Flange Gaskets

Data centers depend on highly reliable on-site power generation and backup systems to maintain uptime during peak demand and grid disruptions. These systems operate under extreme heat, pressure, and thermal cycling, where conventional graphite materials can oxidize, stick, or degrade over time. Garlock THERMa-PUR is a hydrophobic, oxidation-resistant gasket material engineered for temperatures up to 1,000°C (1,832°F), maintaining seal integrity in high-temperature exhaust, turbine, and generator applications. With excellent torque retention and non-sticking performance, THERMa-PUR helps reduce leakage, maintenance time, and risk in critical data center power infrastructure.

Additional Sealing Solutions

Style 1303-FEP Compression Packing

- Suited for valve stem sealing and is fire safety tested

- Temperature range of -328°F - 850°F

- Complies with stringent VOC and VHAP emission regulations

MULTI-SWELL™ Style 3760 Pipe Flange Gaskets

- Creates its own compressive load to reduce leaks in difficult to seal split case pumps

- Reduces maintenance costs and downtime

Style 1306 Compression Packing

- Graphite base packing dissipates heat so you can tighten valves to reduce leakage

- Non-damaging to pump shafts and sleeves to reduce maintenance costs

- Self-lubricating

Style P2000 Expansion Joints

- Absorbs movement to protect system components

- Isolates vibration to reduce noise and damage

- Delivers durability for high-demand cooling systems

Engineering the Future of Data Center Cooling and Power

As the data center landscape evolves toward higher power densities and advanced liquid cooling, Garlock remains at the forefront of the industry. Through our active participation in the Open Compute Project (OCP), we directly contribute to and stay ahead of the latest standards in cooling and power generation. This involvement ensures that our sealing and material solutions are not only compliant but are specifically engineered to solve the emerging thermal and environmental challenges of next-generation facilities.

Beyond the products featured on this page, Garlock houses a dedicated team of material experts and applications engineers ready to tackle your most complex requirements. We invite you to partner and collaborate with us to develop custom engineered solutions, leveraging our 135-year legacy of innovation in polymers and high-performance materials, to build more efficient, reliable infrastructure.